Steel Bending

The process of bending steel has been considered as one of the most important and the most relevant procedures in metal fabrication and without it, an abundant amount of the things we see and know would not be existent – from the computers, laptops, and smartphones we use on a daily basis, to the designs and the engineering of the buildings and establishments we know.

Steel bending is one of the few processes that make metal fabrication a unique experience and industry. Compared to the regular bending of wood and plastic, steel bending would require hard exertion of force and pressure – and this is to shape metals, steels, as well as other types of alloys.

Not a lot of companies and businesses have been blessed to have the knowledge and the skill in manipulating metals, steels, and different types of alloys here at Indiana Contract Manufacturing Professionals. We’ve been the professionals that many companies and businesses have regarded as their go-to company.

The Importance of Steel Bending

From the simple fact and evidence of the things we use and see every day, to the different factors affecting the relevance and the importance of steel bending; here are some of the reasons why steel bending should never be left out in the entire metal fabrication process:

- Steel bending controls the form and the shape of the material or the workpiece

- The steel bending process is responsible for the creation of some parts and components such as I-Beams, Channels, Tubing, etc.

- Without steel bending, all metals would be metal sheets

So if you are a business or a manufacturer and you are looking for a company to whom you can outsource the bending of your metal sheet, you’ve come to the right place because we here at Indiana Contract Manufacturing Professionals are the best in it.

Our Usage of CNC Press Brakes

We at Indiana Contract Manufacturing Professionals utilize computer numerically-controlled press brakes – you guessed it right, they’re the kind of press brakes that needs less human intervention and supervision because it runs on a program.

The design or the engineering of the product you want us to produce will be converted by us into a file that can be read by our machines and then we’ll load it up to our CNC machinery.

Until the time that the machine is stopped, turned off, or if the design is changed and modified, the machine will be producing the exact copies for as long as it’s functioning.

Our Unique Procedures

Because of the CNC machinery we utilize, clients love working with us because they know that they’ll be able to trust the products and the outputs that we manufacture and produce.

Should you need a high-mix, low-volume type of production, small batch production, or even mass production, Indiana Contract Manufacturing Professionals is always here and ready to help.

Clean and Neat Steel Bending Procedures

Using our CNC press brake machines, our experts and fabricators can guarantee clean and neat bends on the metal sheets and the steels that you have. With its automation, there’ll be little-to-no problems in the accuracy and the precision of the workpieces.

As opposed to using manual machines, CNC press brakes can get you the best and the highest quality of steel bending you need.

Faster Production of Bent Steel

The automation of the press brake machines makes it easier for us to produce the bent steel that you’re looking for faster and better. Don’t believe us? Well, our CNC press brakes can make a total of 800 to 900 bends in an hour – and take note, that’s a single machine.

One thing that we tell our clients is that they will never have to worry about the speed and the urgency that our machines can provide – they’ll all be working efficiently.

Those are only a few benefits and advantages of working with us. Sure, some other companies, manufacturers, and fabrication companies utilize CNC machines too but are they using it efficiently the same way we here at Indiana Contract Manufacturing Professionals do?

All our experts and professionals have been in the industry for a long time and we have always given our clients the type and the quality of formed and bent steel that they needed and wanted – no matter what business or industry they might be in!

Process of Steel Bending

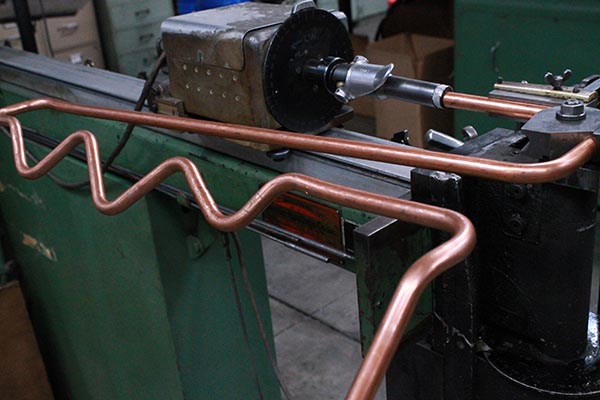

The steel bending process is simple – and in most cases, companies utilize a press brake or a box & pan to form and bend the materials. Its process is as follows:

- When the material or the workpiece is finalized, it is placed in between the “punch & die,” where the former is the one that would exert the force and the latter is the shape of what the metal sheet will be;

- Upon execution, the force that the punch would provide will be pushing the material towards the die, helping it to bend and take on the form that’s wanted and needed;

- The process is repeated several times until the exact amount of the products is met.

Contact Us Now!

Are you looking for a company that can help you with the forming and shaping of your steel? Wherever you may be in Indiana, we here at Indiana Contract Manufacturing Professionals are the best company you will ever work with.

Never did any of our clients give us any type of negative feedback or comment – we’re always left with a positive upbringing of our services; and they spread the word too!

As a metal fabrication company, Indiana Contract Manufacturing Professionals focuses on the quality and the caliber of the products and the outputs we provide our clients. No matter how complex our clients’ requests are about steel bending, we make sure that we meet their expectations.

Call us now and get the quotation that you need! You’ll never experience the world-class quality services we offer with any other company again! Achieve the highest quality of fabricated steel and metal with us at a price that you will absolutely fall in love with!

Indiana Contract Manufacturing Professionals has the capacity to deliver all the above services. You will get high-end solutions at the most affordable rates in the region.

Our core offerings and services at Indiana Contract Manufacturing Professionals includes, but is not limited to, the following below:

We service multiple cities throughout the state of Indiana. We provide all the services listed above, and much more in every city throughout Indiana.

If you don’t see your city listed or a specific service listed, don’t worry. All you have to do is contact us by either giving us a call or filling out our online contact form. Then we’ll discover what are some of the top solutions for you, your business, and executing a solid solution.