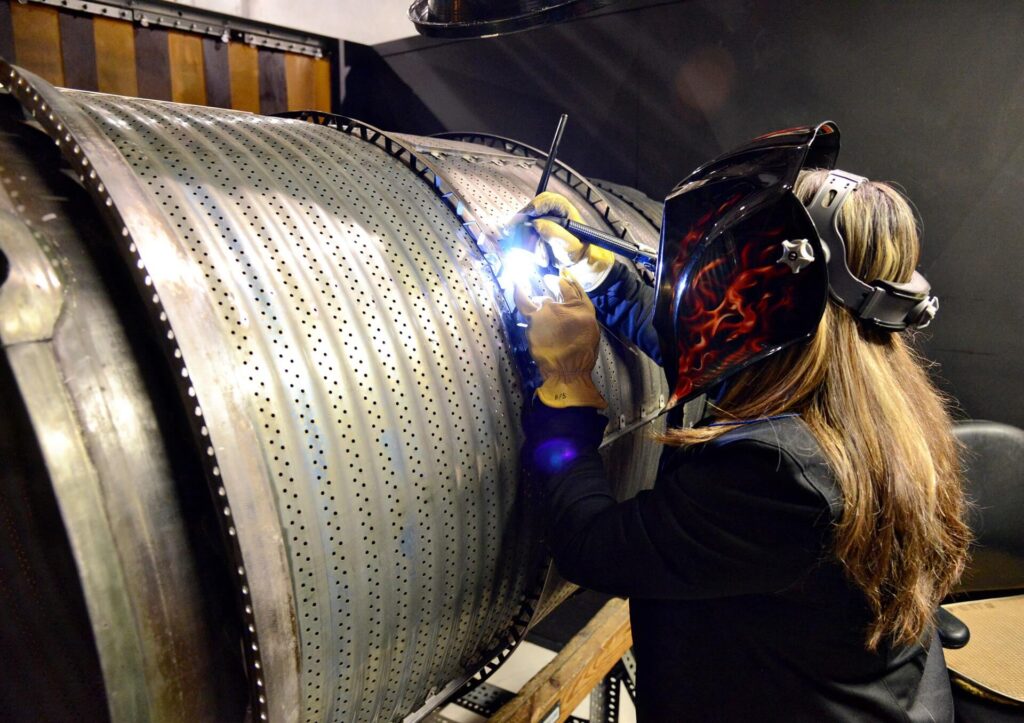

TIG Welding

There are many different types and kinds of welding and TIG or tungsten inert gas welding is one of the most common. Because of its trait of utilizing non-consumable tungsten for the weld, it’s a fan-favorite especially by manufacturers and fabricators that continuously perform welding.

Similar to MIG or metal inert gas welding, the power of TIG welding also comes from a welding machine and instead of using a copper wire or another type of wire as its electrode, it uses tungsten.

Should you find yourself needing a company that you can count on, we here at Indiana Contract Manufacturing Professionals are always open for any kind and type of request that you might need. Currently under our employ are the best, the most experienced, and the most dedicated welders in the industry.

Our People

When it comes to any process in metal fabrication, you can count on us because we have not only the most experienced staff and people but also the most knowledgeable and the most skilled in their specific craft.

Not only are we the best company when it comes to welding, but you can also count on us to help you in many different metal fabrication procedures too including the metal and steel cutting process, the bending, forming, and shaping process, the welding process, the rolling process, the finishing, and even the assembly.

Welding Expertise and Mastery

Let’s now focus on one of our key strengths and skills – welding. Indiana Contract Manufacturing Professionals is a company filled with the most talented welders with decades of experience doing what they love doing best.

One of the best welding procedures that we perform is TIG welding and it’s the type of welding that uses non-consumable tungsten as the electrode. Let us dive deeper into the process and learn about TIG welding and what it can do for you and your business.

What is TIG Welding?

Akin to how MIG or gas metal arc welding (GMAW) is done, TIG welding or gas tungsten arc welding follows the same process. The only difference is that it uses tungsten, dubbed as “non-consumable” as its electrode.

Tungsten is the one used in this scenario because of the fact that it has a high melting point than most wires and other electrodes. It’s really not “non-consumable” because after so many uses, the tungsten deteriorates, too.

It only has a higher and a farther melting point which means it does not burn as quickly as the other types of wires and electrodes.

Why Trust Our TIG Welding?

The main purpose of welding is to fuse and combine two pieces of steel and metal together using the conduction of heat – by melting it, cooling it again. Out of all the different companies and businesses that perform different kinds of welding, why should it be us that you’ll choose? How can we provide a better and a higher caliber of weld compared to the products and the outputs delivered by other companies?

When it comes to the choosing and the decision, it will all be revolving around what you can get from our TIG welding. Good thing we’ve prepared a list of the benefits and the advantages that you can actually get from us here at Indiana Contract Manufacturing Professionals.

Some of which include:

Wide Variation of Welding Positions

When doing TIG welding, you will be able to operate and perform it no matter what welding position you choose; whether you are going to weld downward, upward, or even sideward – it’s all going to be effective and possible!

Several welding methods and procedures have their recommended welding position – that’s a no-no with TIG welding! You can weld in whatever position you want and it’s never going to affect the overall result of the weld!

More Precision in Welds

Because of the fact that TIG welding is a lot more difficult than the different types of welds, it can give you the guarantee that the welds that you’ll create will be more accurate and precise. Operating and doing TIG welding correctly can actually help you achieve the precision and the accuracy that you need.

With us here at Indiana Contract Manufacturing Professionals, you’ll never have to worry about the exactness and the accuracy of the welds – it’s all given!

Cleaner and More Organized

TIG welding is one of the few welding procedures that does not utilize filler metal. Should you need or want filler metal, it can be added easily by hand – and it’s not going to take too long. In addition to that, TIG welding utilizes Argon which is usually safer when mixed with other chemicals.

But that shouldn’t worry you too because similar to MIG welding, TIG welding also produces a gas shield to prevent chemical mixing to transpire while the welding is taking place. This gas shield protects the elements that are active during the welding process, keeping them safe from any type and kind of dangerous chemical reaction.

Fewer Fumes and Smoke

This feature or characteristic goes in line with producing cleaner and more organized welds. Because of the fact that it uses Argon, it creates less fumes and less smoke that can interfere with the entire welding process.

However, you might find times that some fumes or smoke will be produced. This is only when the types of alloys, metals, or steels that you’re working on contain elements and contaminants. This could be hazardous, though, and this can interfere with the welding procedure.

We Are Definitely What We Offer

Other companies and metal fabrication companies like to say sweet words whenever they’re trying to win clients over. But when you work with us here at Indiana Contract Manufacturing Professionals, everything we say we do – we do!

You’ll never have a problem when you work with us especially when it’s with TIG welding. You can get the world-class quality services you’ve been looking to experience in just one call! Contact us and get the quote for the welding service or assistance that you need!

Indiana Contract Manufacturing Professionals has the capacity to deliver all the above services. You will get high-end solutions at the most affordable rates in the region.

Our core offerings and services at Indiana Contract Manufacturing Professionals includes, but is not limited to, the following below:

We service multiple cities throughout the state of Indiana. We provide all the services listed above, and much more in every city throughout Indiana.

If you don’t see your city listed or a specific service listed, don’t worry. All you have to do is contact us by either giving us a call or filling out our online contact form. Then we’ll discover what are some of the top solutions for you, your business, and executing a solid solution.